print version of this document

Fume hoods are installed in laboratories to protect workers from hazardous vapors generated by laboratory experiments. However, simply conducting these experiments in the fume hood does not guarantee adequate protection. The fume hood must be used properly. These guidelines will help you optimize the effectiveness of your fume hood.

Reduce obstructions in the fume hood to improve its effectiveness by allowing adequate air flow across the working surface with minimum turbulence.

- Minimize the number of objects stored in the hood – keep at least 50% of the working surface clear, if possible.

- Always place containers and equipment at least six inches into the hood from the face.

- Place containers and equipment toward the sides of the hood to reduce obstruction of the exhaust slots.

- If possible, elevate equipment and containers two to three inches above the working surface using perforated or slotted shelving to minimize disruption to the airflow.

Check the airflow indicator prior to use to ensure the fume hood is drawing air. Some hoods are equipped with airflow monitors that display a digital readout of the face velocity and/or beep or light up when the velocity is too low. If an airflow monitor is not installed, test the hood airflow with a piece of light material (such as a tissue or chemwipe) held to the bottom of the sash. The material will deflect inward if the hood is drawing air.

Keep the sash at 18 inches or less from the working surface while working in the hood to ensure maximum flow rate and to protect yourself from potential chemical splashes or explosions. The sash should be closed when you are not working in the hood.

Work at least 6 inches into the hood from the face to minimize the potential for fumes to escape. As a useful reminder, place a strip of tape at this six-inch limit.

Keep laboratory doors and windows closed and limit movement in front of the hood. Most laboratory ventilation systems are designed for labs to have all doors and windows closed. Open doors and windows can alter the air balance in the room and disrupt the airflow in the hood. Also, open doors and windows and traffic or movement in front of the hood can create turbulence resulting in vapors flowing out of the hood’s interior.

Fume hoods are not the same as biosafety cabinets. Laboratory hoods and biosafety cabinets (or tissue culture hoods), although similar in appearance, are different devices. Biosafety cabinets are designed for protection against exposure to biological materials and for protection against contamination of biological experiments and typically offer no protection against chemical vapors. Refer questions concerning biosafety cabinets to the OCRS Biosafety Officer (322-2057).

If your hood is not working properly, contact Facilities Management for assistance. Please contact OCRS if you have questions regarding proper use of your fume hood or if you would like to have your fume hood tested.

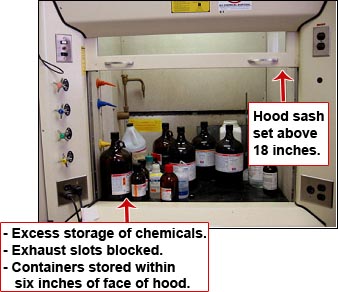

Example of a fume hood that has been set up incorrectly.

- There are too many chemicals stored here.

- Exhaust slots are blocked.

- Containers are stored too close (within 6 inches) of the face of the hood.

- Hood sash is set too high (above 18 inches).

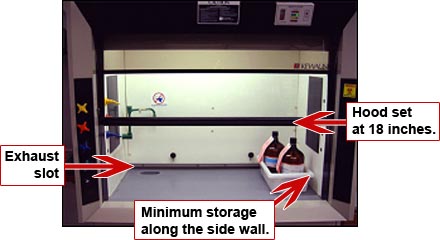

Example of a fume hood that is set up correctly.

- In this example, the fume hood sash is set at the proper height (18 inches).

- The exhaust slot has not been blocked.

- There is only minimal chemical storage in the hood.

See also Fumehood Safety Inspections and Lab Safety Links.